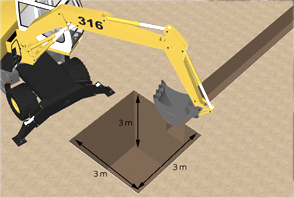

Make the foundation hole

Carry out the excavation work and the trench corresponding to the place where the equipment will be connected.

The average hole consists of about 3x3x3 meters for towers of 20m in height and it is recommended to make a concrete cleaning and reinforcing concrete to give it more strength. This job requires an excavator and a supervising installer technician only.

The estimated execution time is 3-4h.

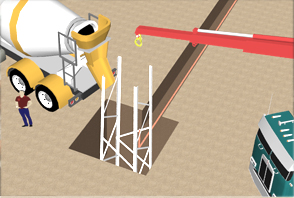

Place the first tower section

When the hole is made, it is necessary to put the wiring tube and insert the first section of the tower to be able to pour the concrete later. 27m3 of concrete is required and the type of concrete can be the building standard of your country. Quick concrete is recommended and that is minimally reinforced for greater strength.

This work requires a small crane to place the tower and an installation technician.

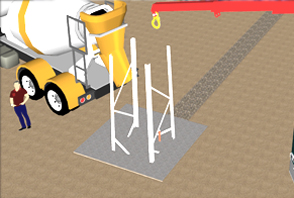

Allow the foundations to set

Depending on the type of concrete used, the solidification time of the foundation can be delayed from 48 hours to 2 weeks.

Once it is consolidated, the next installation process will proceed.

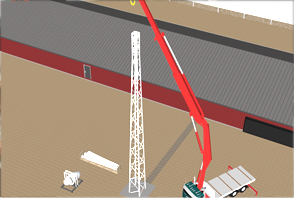

Mount the tower on section one

Once the foundation is dried, the tower is completely assembled on the cemented section.

This requires a standard crane that can lift the boom to a height of 18-22m depending on version and with a load capacity of 2,400 kilos.

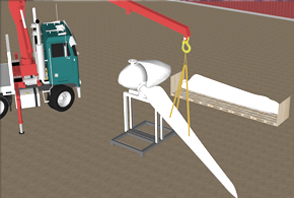

Mount the blades on their packing structure

The packaging structure with which the wind turbine is transported is ready to be placed on it and used as a mounting base.

By placing the wind turbine on it, with the crane the blades of the lower part are first mounted and then the upper blade. For this work 2 people are recommended, plus the help of the crane.

Raise the wind turbine and screw the tower

With all the blades already assembled, the upper casing is removed and the entire wind turbine is taken from the special rings it has inside to raise it to the top of the tower.

Once the crane is located at the top one or two operators from a lift platform or from another crane with basket, screw the wind turbine to the tower and make the electrical connections of the cables between the tower and the nacelle.

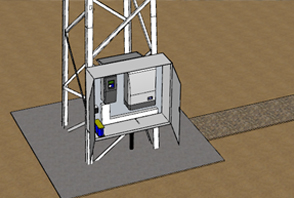

Electrical installation

Once the installation of heavy parts, the third day is carried out to perform the electrical installation, connections and commissioning of the installation.

To do this, the cabinet is placed at the base of the tower and the connections are made, all the cables of the wind turbine are Plug & Play.